Description

Here are key aspects related to machining aerospace and defense industry parts:

- Materials:

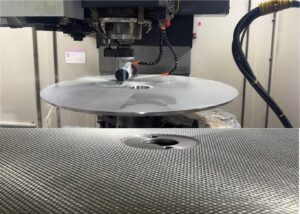

Aerospace and defense components are often made from high-performance materials such as titanium, aluminum alloys, high-strength steels, and advanced composites. Material selection is critical for meeting specific requirements like weight reduction, strength, and resistance to extreme conditions. - Precision Machining:

Precision is paramount in aerospace and defense machining to ensure the accuracy and reliability of critical components. CNC machining, including multi-axis machining, is widely used to achieve tight tolerances and high levels of precision. - Complex Geometries:

Many aerospace and defense components have complex shapes and intricate geometries. Machining techniques, such as 5-axis milling, are employed to produce components with complex features like airfoils, turbine blades, and intricate structural elements. - Heat Resistant Components:

Some components in aerospace applications, such as turbine blades and engine components, are exposed to high temperatures. Machining processes may include the use of heat-resistant materials and specialized techniques to withstand extreme thermal conditions. - Surface Finish:

The surface finish of aerospace and defense components is critical for aerodynamics, corrosion resistance, and fatigue life. Machining processes are controlled to achieve the required surface finish, and additional treatments may be applied for protection against corrosion. - Weight Reduction:

Weight is a crucial factor in aerospace design. Machining processes may involve techniques such as high-speed machining and advanced milling strategies to achieve optimal weight reduction while maintaining structural integrity - Quality Control:

Rigorous quality control measures are implemented throughout the machining process to ensure that aerospace and defense components meet strict industry standards. Inspection processes include dimensional checks, material testing, and non-destructive testing. - Regulatory Compliance:

The aerospace and defense industries are highly regulated, and components must comply with aviation and military standards. Machining processes must adhere to these regulations to ensure the safety, reliability, and certification of aerospace and defense products. - Tight Security and Confidentiality:

Machining in the defense sector often involves classified or sensitive projects. Strict security measures are implemented to protect intellectual property and ensure the confidentiality of designs and specifications. - Small Batch Production:

Aerospace and defense components are often produced in smaller quantities compared to other industries. Machining processes must be adaptable to small-batch production while maintaining high precision and quality.

Examples of aerospace and defense components that may undergo machining include aircraft structural parts, engine components, avionics housings, missile components, and various critical parts used in defense systems.

In summary, machining plays a critical role in the aerospace and defense industries, where precision, reliability, and adherence to stringent standards are paramount. Advanced machining technologies and strict quality control measures are employed to meet the specific requirements of these high-performance and safety-critical applications.