Description

Here are key aspects related to machining customized engineering product parts:

- Materials:

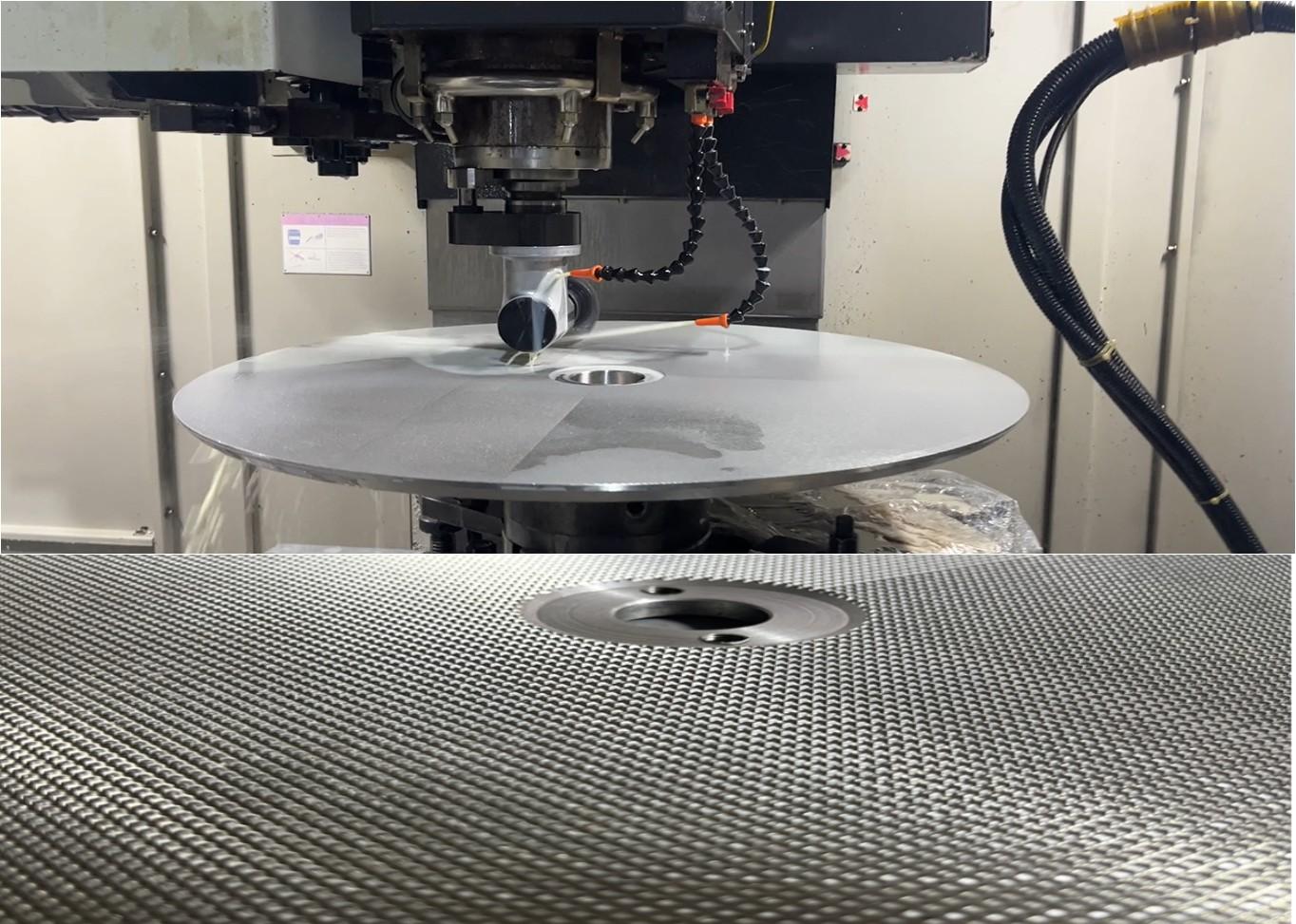

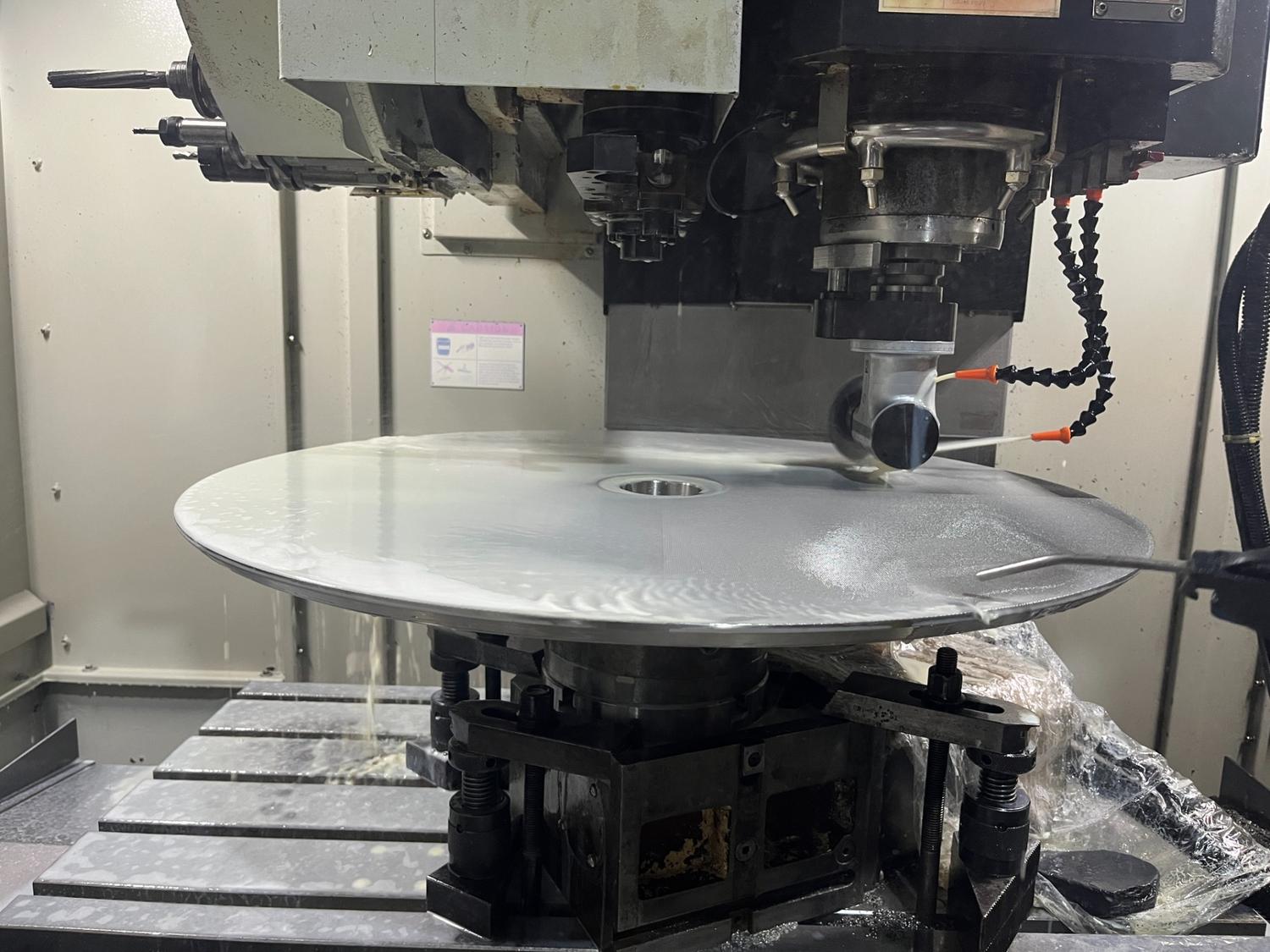

The choice of materials depends on the specific engineering application. Common materials include metals such as steel, aluminum, titanium, and various alloys, as well as plastics and composite materials. - Precision Machining:

Precision is paramount in the production of customized engineering product parts to meet the exact specifications of the application. CNC machining is commonly used for precision machining, enabling tight tolerances, high accuracy, and repeatability. - Customization and Prototyping:

Customized engineering product parts often require prototyping and customization to meet specific design requirements. Machining allows for the efficient production of prototypes and the customization of parts based on engineering specifications. - Complex Geometries:

Engineering product parts can have complex shapes and intricate geometries. Machining techniques, including multi-axis machining and precision milling, are employed to produce components with complex features. - Surface Finish:

The surface finish of engineering product parts is important for both functional and aesthetic reasons. Machining processes are controlled to achieve the required surface finish, considering factors such as smoothness, texture, and corrosion resistance. - Functional Features:

Engineering parts may have specific functional features, such as threads, grooves, or intricate patterns. Machining processes are tailored to produce these features with precision, ensuring the proper functionality of the components. - Quality Control:

Rigorous quality control measures are implemented throughout the machining process to ensure that customized engineering product parts meet strict industry standards. Inspection processes may include dimensional checks, material testing, and functional testing. - Regulatory Compliance:

Depending on the industry, customized engineering products may need to comply with specific regulations and standards. Machining processes must align with these regulatory requirements to ensure the safety and performance of the parts. - Small to Medium Batch Production:

Customized engineering product parts may be produced in relatively small to medium-sized batches. Machining allows for efficient production while maintaining high precision and quality standards.

Examples of customized engineering product parts that may undergo machining include specialized components for machinery, aerospace structures, medical devices, electronic devices, and various engineering applications where precise and customized components are required.

In summary, machining plays a vital role in the production of customized engineering product parts, where precision, customization, and adherence to industry standards are crucial. Advanced machining technologies and stringent quality control measures are employed to meet the specific requirements of engineering applications across diverse industries.